The advent of waterjet cutting machines equipment has transformed precision cutting techniques across sectors including aerospace, automotive, manufacturing, and small-scale fabrication. Businesses seeking production optimization prefer these tools because they cut various materials with exceptional precision while generating minimal waste. Selecting a waterjet cutting machine becomes an overwhelming challenge because the vast number of options complicates the assessment of cost in relation to performance and future benefits. This guide delivers an intricate examination of how to choose the right waterjet cutting machine equipment while decoding its price structure to aid your decision-making process.

What is a Waterjet Cutting Machine Equipment?

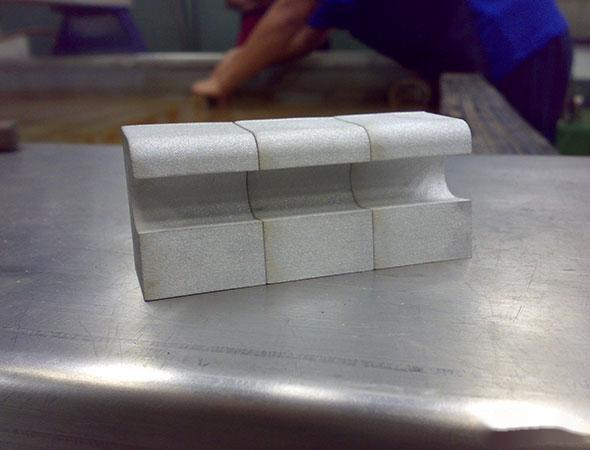

The waterjet cutting machine equipment utilizes high-pressure water streams combined with abrasive particles such as garnet to achieve precise material slicing. These machines function within pressure ranges of 60,000 to 90,000 psi to cut a variety of materials including soft rubber and foam as well as hard steel, titanium, stone, and glass. Waterjet cutting stands apart from conventional methods like laser and plasma cutting because it operates as a cold process which results in the absence of heat-affected zones (HAZ). The process prevents material distortion and property alteration which makes it perfect for heat-sensitive uses.

Waterjet machines come in two main types:

- Pure Waterjet: Uses only water, suitable for softer materials like textiles, rubber, or food products.

- Abrasive Waterjet: Combines water with an abrasive material, designed for tougher substances like metals and ceramics.

Understanding this distinction is the first step in determining which machine aligns with your needs.

Key Factors to Consider When Choosing a Waterjet Cutting Machine Equipment

The process of choosing an appropriate waterjet cutting machine equipment involves analyzing your unique needs alongside production objectives and operational limitations. Numerous essential elements exist to direct your decision-making process.

1. Cutting Capabilities and Size

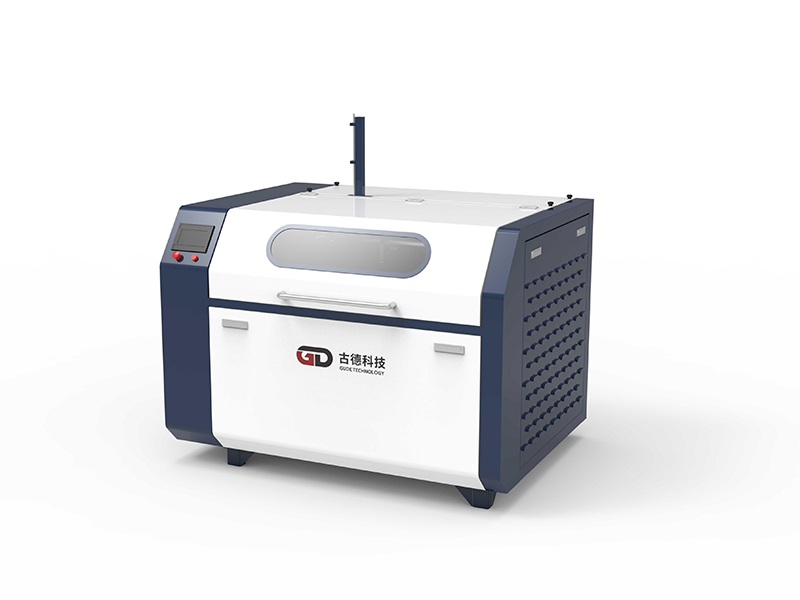

Machine bed size and power requirements depend on the dimensions and density of the materials you intend to cut. Waterjet cutting machine equipments exist in forms that span from small tabletop versions with 2’ x 2’ cutting areas to huge industrial configurations measuring 10’ x 20’ and beyond.

- Small Machines: Perfect for prototyping, small businesses, or hobbyists working with sheets under 4’ x 4’. These are cost-effective and space-efficient but limited in scope.

- Medium Machines: Typically 4’ x 8’ or 5’ x 10’, these suit most general fabrication shops cutting standard material sizes like metal sheets or stone slabs.

- Large Machines: Designed for heavy industrial use, such as cutting aerospace components or large architectural panels, these offer expansive cutting areas and higher throughput.

Example: Metal fabricators who handle 4’ x 8’ steel sheets find that medium-sized machines with corresponding bed dimensions deliver efficient performance while avoiding the costs of larger models.

Evaluate the Z-axis (height adjustment) alongside other factors because machining thicker materials such as 6-inch steel plates demands equipment with increased vertical clearance and strong support structures.

2. Material Compatibility

While waterjet cutting stands as a versatile tool, disparities exist among machines regarding their material handling capabilities. The selection process relies upon the material’s hardness, thickness, and sensitivity.

- Soft Materials: Pure waterjet systems demonstrate exceptional performance when cutting soft materials such as foam, rubber, leather, and food items including cakes in commercial kitchens. These machines are simpler and cheaper.

- Hard Materials:The use of abrasive waterjets is essential for processing metals like steel, aluminum, and titanium as well as ceramics, glass, and composite materials. Examine the abrasive delivery system alongside nozzle durability to ensure consistent machine performance.

- Special Cases: Reflective materials like copper and brittle ones such as tempered glass demand distinct setups and cutting methods to prevent potential damage.

Tip: Businesses that process diverse materials like stainless steel and acrylic should select abrasive waterjets with adjustable pressure settings to achieve operational flexibility.

3. Pump Power and Efficiency

A waterjet cutting machine equipment relies on its pump as a core component which defines both its cutting strength and operational effectiveness. The categorization of pumps depends on their pressure output combined with their structural design type.

- Pressure Range: The majority of pumps function within a pressure range from 60,000 psi (standard) to 90,000 psi (high-performance). Increased pressure enables quicker cutting speeds and deeper material penetration for thicker substrates like 8-inch steel compared to thinner ones like 2-inch aluminum.

- Pump Types:

- Direct-Drive Pumps: It performs well in small-scale applications due to its affordability and compact design but lacks durability for continuous operation.

- Intensifier Pumps: Despite its initial expense, this heavy-duty industry-standard tool delivers reliable performance with consistent pressure output and extended durability.

Efficiency Matters: The deployment of high-efficiency pumps curtails both water usage and electricity demand which results in decreased operational expenses. A 50-horsepower pump operating at 60,000 psi may consume 30-40 gallons of water per minute whereas an eco-friendly model reduces this usage by 20%, resulting in substantial annual savings on utility bills.

4. Cutting Speed and Precision

Industries requiring tight tolerances experience direct effects on productivity and product quality from both speed and precision.

- Cutting Speed: The rate measured in inches per minute (IPM) demonstrates variation according to material type and thickness. A machine that cuts 1/4-inch aluminum at 50 IPM reduces its speed to 10 IPM when working with 1-inch steel. Increased operational velocities enhance production rates yet potential edge fidelity deterioration emerges as a trade-off.

- Precision: Precision expressed as tolerance (e.g., ±0.003 to ±0.005 inches) remains essential for aerospace components and medical implants. Systems incorporating advanced motion control elements like servo motors and linear drives achieve exceptionally precise tolerances.

Trade-Off: The use of high-speed cutting techniques often results in rougher edges which necessitate additional finishing processes. When precision remains critical select a machine equipped with dynamic waterjet technology such as tiltable cutting heads to offset taper while preserving accuracy.

5. Automation and Software

Contemporary waterjet machines utilize automated systems and software programs to enhance operational efficiency while minimizing human mistakes.

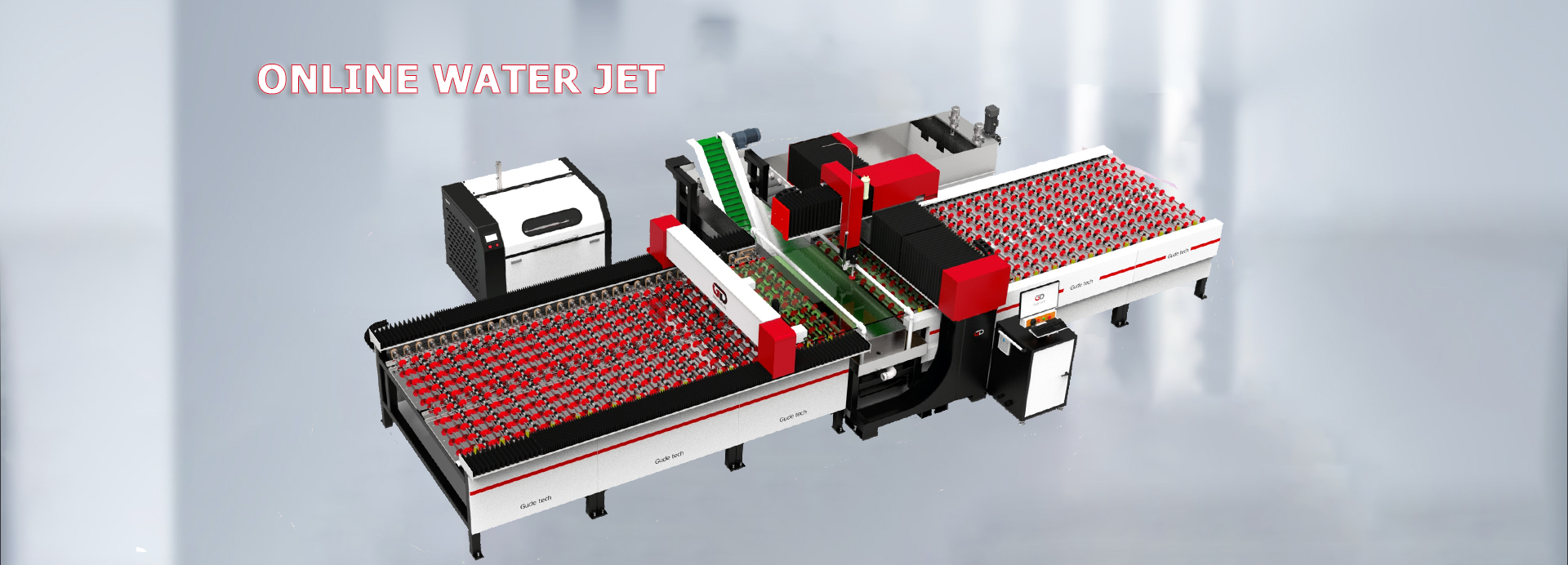

- Automation: Systems incorporating automatic material handling along with multi-head cutting and robotic integration reduce both workforce requirements and operational pauses. These systems enable high-volume shops to achieve double their production rates.

- Software:The integration of CAD/CAM systems enables the optimization of cutting paths while simultaneously nesting parts to minimize waste and simulating cuts prior to execution. Seek interfaces that maintain user-friendliness while ensuring compatibility with your current design tools such as AutoCAD and SolidWorks.

- Advanced Options: Numerous machines deliver immediate monitoring capabilities for elements like pressure and abrasive flow while providing predictive maintenance notifications to prolong operational lifespan and avert expensive failures.

Example: Stone tile shops using nesting software to cut intricate designs could reduce material expenses by 15-20% and recover their software investment within a few months.

Understanding the Price of Waterjet Cutting Machine Equipments

Basic waterjet cutting machine equipments start at $30,000 while advanced industrial systems exceed $500,000 in cost. The cost drivers are explained in detail here.

1. Machine Size and Complexity

The cost of larger machines with expanded beds and multi-axis functionalities (such as 5-axis for 3D cutting) rises because of heightened material requirements and complex engineering demands. An entry-level 2’ x 2’ pure waterjet system begins around $25,000 whereas advanced 10’ x 20’ abrasive 5-axis systems can surpass $400,000.

Complexity: The addition of dual cutting heads for simultaneous cuts or rotary attachments for cylindrical objects increases the base price by $50,000 to $100,000.

2. Brand and Quality

Flow, OMAX, and KMT establish high market values through intricate support systems alongside unmatched precision and reliability standards. An OMAX mid-tier machine demands a $150,000 investment whereas an equivalent off-brand model stands at $100,000 yet it faces potential increased downtime and less robust warranties.

Warranty: Leading brands typically offer 1-3 year warranties alongside lifetime technical support which businesses focused on uptime find worth the additional expense.

3. Customization and Additional Features

Custom features escalate costs quickly:

- Specialized Nozzles: Abrasive cutting systems may require an investment of $5,000 to $10,000 for high-durability nozzles..

- Multi-Axis Cutting: Transitioning from 2D to 5-axis technology results in expenditure increases starting at $50,000.

- Abrasive Removal Systems: The integration of automated garnet removal systems demands an investment of $20,000 while simultaneously eliminating extensive manual cleanup hours.

Example: An aerospace titanium cutting machine equipped with a 90,000 psi pump and 5-axis head might drive expenses beyond $300,000.

4. Maintenance and Operating Costs

The sticker price is just the beginning—ongoing costs can make or break your budget.

- Consumables: The financial expenditure for abrasives like garnet registers as zero dollars. 25-$0. The cost stands at 50 per pound while heavy usage rates reach 1-2 pounds per minute. The replacement frequency for nozzles and seals stands at every 50-100 hours with costs ranging from $100 to $500 per unit.

- Utilities: Filtered water to prevent pump damage along with electricity for a 50-hp pump results in monthly costs ranging from $500 to $1,000.

- Maintenance: The yearly maintenance expenses span from $2,000 for basic services to $10,000 for intricate systems.

Tip: Machines featuring modular designs like replaceable pump seals offer lower repair expenses than fully proprietary systems.

Conclusion: Finding the Right Waterjet Cutting Machine Equipment for Your Needs

Selecting the perfect waterjet cutting machine equipment demands a careful equilibrium between production requirements and financial limitations. Commence the process by establishing your key objectives: Determine whether you require rapid output for large quantities, detailed accuracy for complex patterns, or adaptable functionality for diverse materials. To guarantee sustained value, consider the total cost of ownership by adding initial purchase price to operating expenses.

A compact metalworking business focusing on thin sheets might find a $50,000-$80,000 machine equipped with a 60,000 psi pump adequate for its needs. An aerospace manufacturer seeking 5-axis precision on thick alloys could find a $300,000+ investment justifiable due to enhanced output and dependable performance.

Invest periods into brand investigation while seeking demonstrations and computing return on investment according to your workload. To obtain industry-specific advice initiate contact with suppliers to request tailored quotes and consultations.