The technique of waterjet cutting stands as an exceptionally adaptable and groundbreaking method utilized across numerous industrial sectors today. Industries pursuing advancement while seeking highly precise and efficient material cutting solutions now rely on waterjet technology as an essential tool across manufacturing, engineering, and production sectors. A high-pressure water jet combined with abrasive particles enables waterjet cutters to slice through numerous materials. This technique enables material cutting with exactness while avoiding heat production which stands as a major benefit compared to conventional cutting methods.

In this article, we will explore what waterjet cutters are, how they work, their applications, available types, and why selecting the right manufacturer is essential for businesses looking to incorporate waterjet cutting technology into their operations.

How Does a Waterjet Cutter Work?

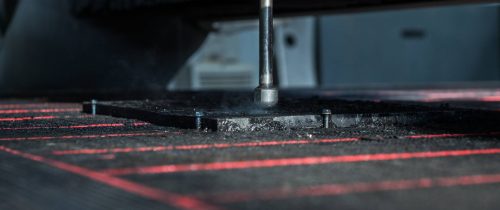

Waterjet cutters operate by increasing water pressure to levels exceeding 60,000 psi (pounds per square inch) which then moves through a minuscule nozzle to create a concentrated water stream. The directed stream impacts the material surface initiating an erosion effect at the contact point. Abrasive waterjets integrate abrasive particles into water streams to boost cutting efficacy on hard materials.

There are two main types of waterjet cutters: pure waterjet and abrasive waterjet.

- Pure Waterjet Cutting: Pure waterjet cutting simply uses a very focused, pressurized stream of water to make precise cuts. This technique employs solely water to cut soft materials including rubber, foam, and certain plastics. Aqua streams attain cutting velocities and exactness while preserving delicate materials from damage or deformation.

- Abrasive Waterjet Cutting: To cut through tougher materials including metal, glass, ceramic, and stone, water is combined with abrasive substances like garnet. The abrasive boosts the water stream’s cutting capability which allows it to penetrate tougher materials.

Pure Waterjet Cutting

Abrasive Waterjet Cutting

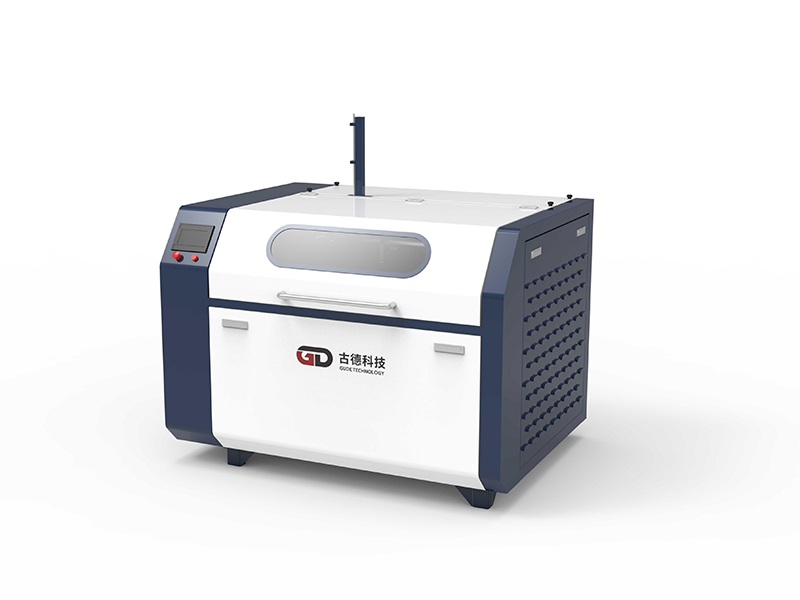

The Key Components of A Waterjet Cutter include:

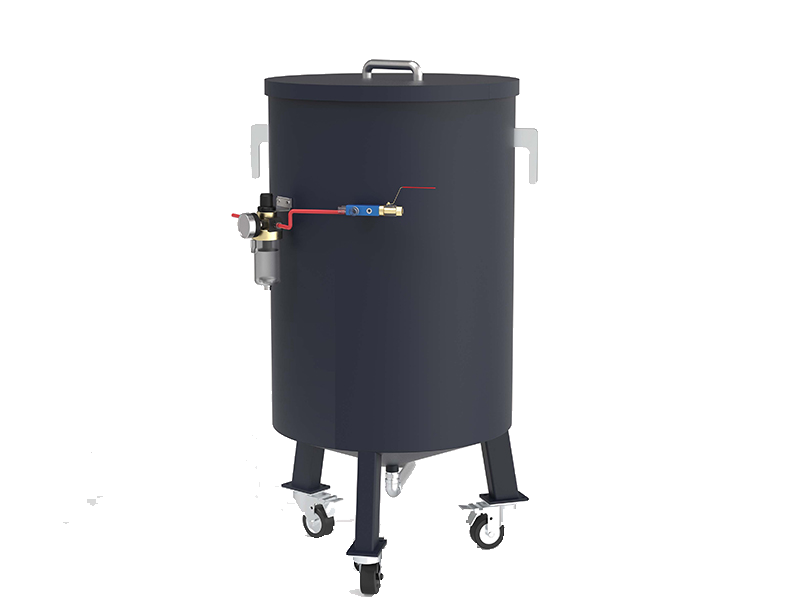

- High-Pressure Pump: This is responsible for generating the high-pressure water stream.

- Cutting Head/Nozzle: The nozzle directs the high-pressure water onto the material being cut.

- Abrasive Delivery System (in abrasive waterjets): This system mixes the abrasive material with water before it is directed toward the cutting nozzle.

- CNC Control System: This system controls the movement of the cutting head to follow precise paths and shapes based on the design or CAD drawing.

High-Pressure Pump

Cutting Head/Nozzle

Abrasive Delivery System

CNC Control System

Applications of Waterjet Cutters

Waterjet cutting technology is used in a wide variety of industries due to its precision, versatility, and ability to handle almost any material. Below are some common applications of waterjet cuters:

- Aerospace Industry: Waterjet cutting is widely used in aerospace manufacturing for cutting materials like aluminum, titanium, and composites. The non-heat-affected cutting process is perfect for maintaining the integrity of these materials, which can be sensitive to heat.

- Automotive Industry: In automotive manufacturing, waterjets are used for cutting parts from sheet metal, composites, and rubber. Waterjet cutting offers the flexibility to produce intricate designs while maintaining tight tolerances, which is critical for automotive components.

- Architectural Design: Waterjets are commonly used in architectural applications for cutting natural stones like granite, marble, and glass. The precision and intricate detailing achievable with waterjet cutting allow designers to create detailed patterns, logos, and sculptures.

- Metal Fabrication: One of the most widespread applications for waterjet cutting machines is in metal fabrication. Whether it’s stainless steel, aluminum, or titanium, waterjets provide clean, precise cuts without the heat-affected zone, which can compromise the material’s integrity.

- Signage and Graphics: The ability to cut complex shapes and designs from various materials like acrylic, plastic, and metal makes waterjet cutting an excellent choice for signage and graphic design industries.

- Mining and Construction: Waterjets are used to cut through tough materials like stone, concrete, and rock. In construction, waterjets are also used to clean and prepare surfaces before additional processing.

- Food Industry: Waterjets are sometimes used in the food industry for cutting through food products like meat, vegetables, and baked goods. Since waterjets don’t produce any heat, there is no risk of contamination, and the process is hygienic.

- Medical and Surgical Tools: In the medical industry, waterjets are used to create precise and intricate cuts in medical devices and tools, ensuring high-quality and sterilized parts.

Benefits of Waterjet Cutting

Waterjet cutter offer numerous advantages that make them an excellent choice for a wide range of industries. Some of the key benefits include:

1. Precision and Accuracy

Waterjet cutting machines are capable of achieving very fine tolerances (typically ±0.005 inches or better), making them ideal for applications where high precision is essential. This is particularly useful in industries like aerospace, automotive, and medical device manufacturing.

2. No Heat-Affected Zones (HAZ)

Unlike laser cutting, plasma cutting, or oxy-fuel cutting, waterjet cutting does not generate heat during the cutting process. This eliminates the risk of heat distortion, warping, or changes in the material’s properties, ensuring that the integrity of the material is preserved.

3. Versatility in Materials

Waterjet cutting machines can cut through a wide variety of materials, including metals, plastics, ceramics, glass, rubber, composites, and more. This versatility makes waterjet cutting suitable for a broad range of industries and applications.

4. Minimal Waste

The precision of waterjet cutting allows for tight nesting and minimal material waste. Additionally, waterjet cutting produces clean, smooth edges that often require little or no secondary finishing.

5. Complex Shapes and Intricate Designs

Waterjets excel in cutting intricate and complex shapes with high precision, which can be challenging for other cutting methods. The flexibility in cutting complex geometries is one of the key benefits of waterjet technology.

6. Environmental Friendliness

Waterjet cutting is considered an environmentally friendly method of cutting since it doesn’t produce harmful fumes or gases. The water used in the process is recyclable, and no toxic chemicals are involved, making it an eco-friendly option.

Types of Waterjet Cutters

There are several types of waterjet cutting machines available, each suited for specific applications. The two main types are:

- 2D Waterjet Cutting Machines: The majority of waterjet cutting machines belong to this basic category. These machines possess the capability to slice through flat materials including metal sheets, stone slabs, and plastic sheets. The cutting head operates across two-dimensional axes X and Y on a flat surface.

- 3D Waterjet Cutting Machines: 3D waterjet cutting machines execute multifaceted and intricate cutting operations. These machines function along three axes (X, Y, and Z) to allow the creation of three-dimensional components and structures. 3D waterjet cutters see widespread application in sectors requiring extraordinary precision and complex tasks such as aerospace and automotive industries.

- Hybrid Waterjet Machines: Hybrid machines integrate waterjet cutting with additional technologies like laser and plasma cutting. Hybrid machines provide enhanced operational versatility enabling them to cut various materials based on specific job requirements.

Why Choose the Right Manufacturer?

Choosing an appropriate manufacturer for your waterjet cutting machine plays a vital role in maintaining operational quality and dependable performance along with cutting efficiency. Several elements demand attention when selecting a producer of waterjet cutting machines:

- Experience and Expertise: Select a production entity that demonstrates long-term reliability and specialized knowledge within the waterjet cutting sector. An experienced manufacturer possesses the capability to deliver essential insights along with support and guidance to help you choose the optimal machine for your requirements.

- Quality of Equipment: Verify that the production capabilities of the manufacturer result in waterjet cutting machines that meet standards of exceptional quality along with durability and reliability. The deployment of superior machinery components minimizes operational interruptions while boosting output and extending machine lifespan.

- Customer Support and Service: Seek out a manufacturing entity that delivers extensive customer assistance programs which encompass installation services along with maintenance support and troubleshooting help. An effective support team ensures your machine operates without problems while resolving any emerging issues.

- Customization: A number of manufacturers provide waterjet cutting machines that can be customized to meet your unique requirements. When faced with distinctive business needs, exploring manufacturers capable of delivering customized solutions becomes a worthwhile consideration.

- Technology and Innovation: Select a production company that dedicates resources to cutting-edge technological advancements and innovative developments. Throughout the years waterjet cutting machines have evolved into complex systems, incorporating state-of-the-art CNC controls alongside advanced pumps and automation which collectively enhance operational efficiency while reducing costs.

Conclusion

Industrial material cutting methods have become unrecognizable due to the transformative impact of waterjet cutting machines. Their ability to perform precise operations combined with versatile functionality and their aptitude for cutting a wide range of materials makes them the tool of choice across many industrial sectors. The aerospace, automotive, and construction industries among others benefit from waterjet cutting because it achieves intricate designs without heat distortion while minimizing material waste.

Choosing an optimal waterjet cutting machine manufacturer guarantees your business obtains premier equipment alongside advanced technology and exceptional support. Integrating waterjet cutting into your production process boosts both efficiency and quality to help your business maintain its competitive edge in the rapidly evolving manufacturing sector.