The manufacturing sector’s dynamic nature demands businesses to attain both precision and efficiency to maintain a competitive edge. Traditional cutting methods prove useful yet encounter significant limitations including thermal distortion, material deformation, and inefficiencies when processing intricate shapes. The waterjet cutting machine emerges as an industrial cutting revolution that redefines precision and versatility while offering eco-friendly performance. This article examines waterjet cutting machine technology along with its major advantages and applications while exploring why these machines represent the future of precision cutting technology.

What is a Waterjet Cutting Machine?

An extremely high-pressure water stream combined with abrasive particles enables a waterjet cutting machine to cut through various materials. Water undergoes complex pressurization to 90,000 psi before passing through a nozzle for precise material cutting. The addition of garnet particles to the waterjet stream enables it to cut through tough materials such as metals and stone.

The defining characteristic that distinguishes waterjet cutting from other cutting technologies is its ability to operate without generating heat.Laser and plasma cutting techniques rely on heat to cut materials while waterjet cutting uses only pressure and water to avoid thermal distortion. Waterjet cutting proves effective for materials such as aluminum, composites, and plastics because it avoids the damage caused by high heat processes.

The Key Features of Waterjet Cutting Machines

- Precision Cutting: The precision capabilities of waterjet cutting machines allow them to maintain exceptionally tight tolerances reaching ±0. 1mm. Their precision makes them perfect for detail-dependent industries where accuracy is essential.

- Versatility in Materials: Waterjet machines possess the capability to cut an extensive variety of materials which include metals, plastics, ceramics, glass, rubber, and composites. The adaptability of these machines enables producers to address an extensive range of cutting operations using a single device.

- No Heat-Affected Zone: A primary benefit of waterjet cutting emerges from its non-thermal nature which removes any possibility of heat-affected zones (HAZ) that might lead to material distortion, fracture, or reduction in strength.

- Complex Shapes and Designs: The process of waterjet cutting excels at producing complex shapes along with detailed patterns and intricate designs. The waterjet’s precision enables manufacturers to produce intricate shapes that other cutting techniques find challenging or unachievable.

Benefits of Waterjet Cutting Technology

The benefits of water jet cutting machine are mainly five points:High Precision and Accuracy, No Heat-Affected Zone, Minimal Material Waste, Environmentally Friendly, and Versatility in Cutting Materials.

1. High Precision and Accuracy

Waterjet cutting technology stands out for its extraordinary precision which establishes its reputation as an exceptionally accurate tool. Conventional cutting techniques rely on blades and lasers that deteriorate and become misaligned with use, whereas waterjet machines function without such elements. The intense water stream pressure facilitates material cutting with exceptional precision to tolerances reaching ±0. 1mm. The aerospace, automotive, and electronics sectors recognize tremendous worth in this technology due to their requirement for supreme precision.

2. No Heat-Affected Zone

Heat distortion and hardened edges were a common problem faced by manufacturers before waterjet cutting was introduced. Waterjet cutting stands out as the superior method over laser and plasma techniques due to its unique capability to function without producing heat. Thermally processed materials form heat-affected zones (HAZ) which cause warping and cracking while potentially weakening structural integrity. The combination of water and pressure as the sole cutting mechanism in waterjet cutting effectively solves this issue making it ideal for heat-sensitive materials like aluminum, titanium, and specific composites.

3. Minimal Material Waste

The waterjet cutting process emerges as a distinctive method due to its ability to execute cuts while producing minimal waste material. Through intricate cutting precision the process achieves denser part nesting which allows more parts to be extracted from each material sheet. Industries dealing with costly or limited material supplies find significant benefit through the combined effects of material cost reduction and waste minimization.

4. Environmentally Friendly

The waterjet cutting process represents an eco-friendly technological method. The primary cutting medium in these processes is water yet the abrasives used can often be recycled which helps reduce environmental damage. This process operates without high heat which prevents the generation of dangerous emissions or fumes during cutting. Industries dedicated to sustainability initiatives consider waterjet cutting as a superb technological choice.

5. Versatility in Cutting Materials

Waterjet cutting machines demonstrate remarkable material handling abilities that distinguish them as versatile cutting tools. Waterjet cutting technology executes precision cutting across a wide range of materials including soft rubber and foam as well as hard stainless steel and granite together with delicate glass. A singular machine capable of processing diverse materials obviates the need for specialized tools while simultaneously boosting operational efficiency.

Applications of Waterjet Cutting Machines

Waterjet cutting is used in industries due to their ability to handle diverse materials produce high-quality cuts and precision cuts. Let’s take a look at some of the most common applications.

Aerospace Industry

The aerospace industry demands an extreme level of precision. Turbine blades along with wing structures and fuselage parts are crafted using waterjet cutting machines. The capability to machine hard materials like titanium and composites without heat production preserves material integrity.

Automotive Industry

The automotive industry extensively employs waterjet cutting to manufacture vehicle components such as body panels, gaskets, and engine parts. Waterjet machines perform precision cutting through steel, aluminum, and carbon fiber materials with ease.

Architecture and Construction

The architecture and construction sectors employ waterjet cutting machines to slice through materials like stone, marble, glass, and tile. The necessity for clean, smooth edges drives waterjet cutting to achieve essential aesthetic and functional standards. The material serves as a medium for creating bespoke designs and detailed patterns across countertops, flooring, and facades.

Food Processing

Waterjet cutting technology causes major disruptions within the food processing industry. Through the application of waterjet technology, cakes, cookies, vegetables, and various food products experience cutting processes. The non-contact operation of the cutting process ensures food integrity and cleanliness which meets essential food safety standards.

Art and Design

The artistic and design community now favors waterjet cutting as their primary technique for crafting intricate and detailed patterns. The machine’s ability to work with metal, glass, and stone allows it to create complex sculptures together with decorative items and architectural elements.

Future of Waterjet Cutting Technology

As manufacturing processes continue to evolve, waterjet cutting is likely to play an increasingly important role. Here’s why:

Increased Automation and Speed

The evolution of CNC (Computer Numerical Control) technology drives waterjet cutting machines to achieve higher levels of efficiency and automation. Artificial intelligence (AI) combined with machine learning is predicted to enhance machine performance which will enable quicker production speeds while maintaining quality standards.

Sustainability Focus

Industries aiming for sustainable operations recognize waterjet cutting as an eco-friendly technique. The demand for sustainable manufacturing techniques propels waterjet technology expansion because it functions without producing fumes or waste materials and emits no harmful pollutants.

Cost-Effectiveness

The anticipated proliferation and automation of waterjet cutting technology will lead to reduced operational expenses in the future. The increased accessibility for small and medium-sized businesses will boost waterjet cutting adoption across various industries.

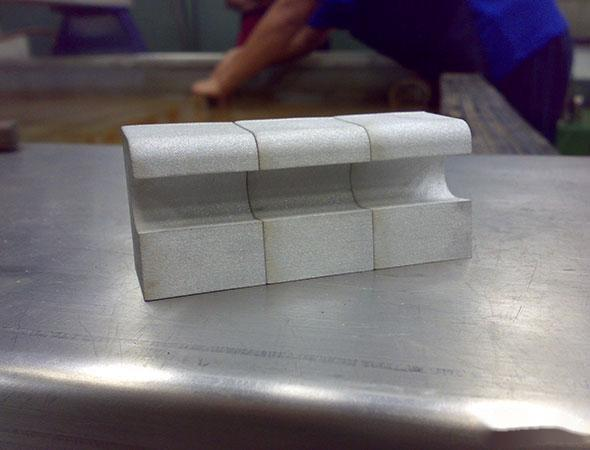

Cutting Sample

Conclusion

The technological advancements in waterjet cutting systems are transforming industrial material cutting methods beyond conventional approaches. The intricate blend of precision performance with versatile functionality alongside environmental advantages positions it as a perfect solution across numerous applications spanning from aerospace technology to food processing industries. The ongoing technological advancements will drive waterjet cutting machines to achieve higher efficiency while becoming more cost-effective and broadly utilized. Precision cutting technology has arrived at its next stage through waterjet power.